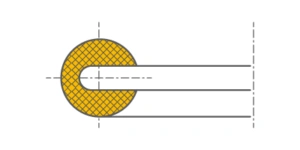

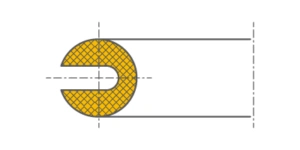

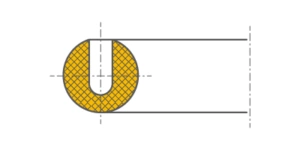

O-rings made of PTFE are used mainly in the chemical industry, pharmaceutics and in medical engineering as static seals in flange connections, caps, etc. Due their good chemical resistance they are compatible with most liquids and chemicals. Exceptions are liquid alkali metals and some fluorine compounds. Furthermore, they are physiologically safe and sterilizable.

Other advantages are their wide operating temperature range from approx. -200 °C to +260 °C and their stick-slip free running capability. Since they are machine cut, they can be manufactured up to a diameter of 1.000 mm in all dimensions.